27.01.2021

In 1863, David Kirkaldy patented his ‘Universal Testing Machine’ and laid the foundations for the Materials Informatics revolution. What did his patented invention mean then, and how can materials informatics inventions be protected now?

Thank you

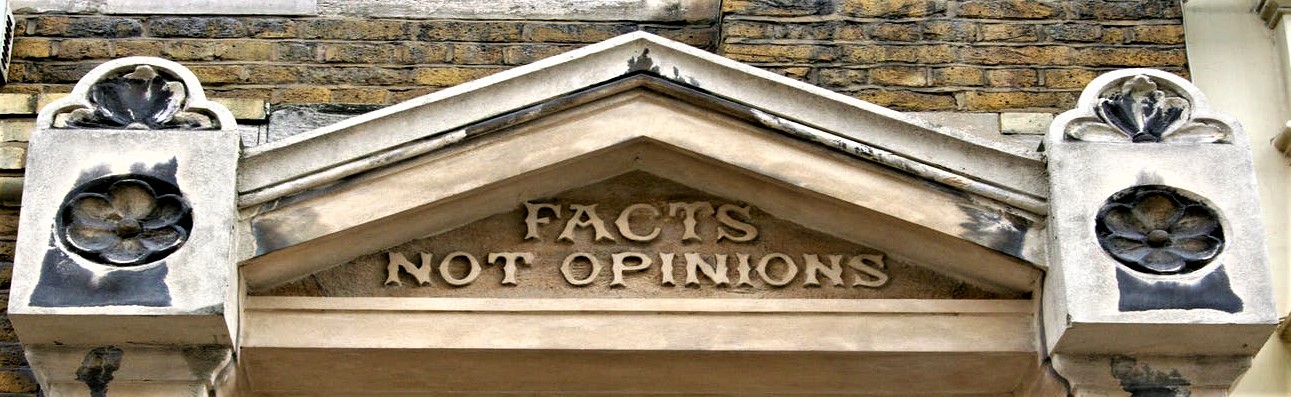

At 99 Southwark Street in London, a few streets from the River Thames and tucked behind the Tate Modern, is a Victorian Warehouse that is home to the Kirkaldy Testing Museum. Volunteer-run, and open a few days a month, it is possible that some people who are not materials science nerds (and maybe even some who are…) have not yet heard of this Materials Mecca. A doorway bearing the epigraph ‘FACTS NOT OPINIONS’ leads to a workshop housing David Kirkaldy’s Universal Testing Machine. Completed in 1865, this huge hydraulic apparatus weighing over 100 tonnes can apply a battery of different failure tests to almost any sample you could imagine, and it remained in use until the 1970s.

The warehouse was specially-built to house the machine. Two large doors on each side could be thrown open to allow huge steel components to protrude from the sides of the building during testing. Some of these components were destined for engineering feats like the original Wembley Stadium and the iconic Skylon building – others were failed components from engineering disasters, such as the 1874 Tay Bridge collapse, or the 1954 explosion of BOAC flight 781.

Kirkaldy started his career at the Napier Foundry Works in Glasgow in 1843. With the Industrial Revolution in progress, he witnessed the development of exciting new engineering materials, including ‘steel’, which was replacing cast and wrought iron in engineering structures. Its properties and capabilities were not yet properly explored, and Kirkaldy realised that to exploit this new material fully, engineers would need to understand it properly. He also realised that if he could develop rigorous testing methods and machinery, then he could make a profitable business offering services in steel and materials testing.

In 1861, Kirkaldy left Glasgow for London, where he set up his own testing works. Here, he developed and built the Universal Testing Machine. The machine’s key asset was its versatility: a great variety of different tests including tensile, compressive, torsion and bending could be applied to samples of all shapes and sizes. It could apply huge forces and measure huge strains, but could do so with a high sensitivity.

Recognising its value, Kirkaldy patented the machine in 1863 (patent no. GB2970) under what was then a recently and radically revised patent system: the first that bore any real resemblance to the ‘modern’ patent system of today. The Patents Act of 1852 had finally established a single UK patent (they were previously separate in England/Wales, Scotland and Ireland), and had set up what is now the UK Intellectual Property Office, so that patents no longer needed to be issued in person by the Monarch. These changes made the patent system simpler and less costly, so that it was accessible to inventors like Kirkaldy as industry and innovation grew with the industrial age.

Kirkaldy’s testing machine is a fantastic piece of Victorian engineering, full of everything you would expect from the industrial age: heavy steel components, hydraulics, weights and counter-weights, the smell of oil and the sounds of moving gears and pistons. The patent gives an excellent feel for this (though of course there is no substitute for a trip to the workshop in Southwark Street).

However, Kirkaldy’s most important invention was perhaps not the patented machine, but something that feels more at home in the modern world than the 1860s, something that is captured in that epigraph above the workshop door. It is the very idea of gathering and processing data, learning systematically and objectively from both failures and successes, and, most contemporary of all, to commoditise that knowledge. Kirkaldy was a pioneer not just in materials engineering, but also in the power of data.

Unlike today, in 1863 a patent could cover multiple inventive concepts: the claims of Kirkaldy’s patent cover the testing machine, as well as various generic uses of levers, dials and pistons that might be applied to other contraptions. Who knows how the patent office of 1863 would have reacted had Kirkaldy attempted to add a claim for his innovations in data capture and exploitation?

If this were a hypothetical new invention today, a patent claim would only make it past the patent office if it were crafted to display a ‘technical effect’. A claim directed purely to collecting and analysing data from samples would not be protectable. But a claim including additional steps of using a particular analysis method to determine optimal parameters of an alloy composition or microstructure with desired mechanical properties, and making a component having that composition or microstructure, could perhaps get granted in the UK now.

While Kirkaldy was ahead of his time in recognising how data could be commercialised, his patent attorney didn’t display quite the same creative thinking in seeking protection for this part of his innovation. In 1863, inventions were in the pistons and metal and oil: Kirkaldy’s methods and use of data would almost certainly not have been seen as an ‘invention’ by anyone, including Kirkaldy himself. He saw this instead as a basic engineering principle that should be common-place, and that should underpin engineering development.

Today, data-driven approaches in materials informatics are thriving. New approaches using AI have given us a paradigm shift in materials R&D. Honing material properties by experiment or traditional computation can be costly and time-intensive. By contrast, a data-driven system that stores a vast amount of materials data and that carries out sophisticated analysis, for example by using machine learning, can predict ways of achieving sought-after material properties, and it can do so quickly, exploring unexpected avenues to give surprising solutions.

Kirkaldy’s innovations in the earliest stages of materials informatics are the foundation that support continued innovation in this area. Today the innovation comes in the analysis techniques used, the capture, storage and use of data, the interactions between systems and their users, and many other areas.

Now that patent practice has evolved, some of the developments in these systems can be patentable, and as innovation grows, so do the patents. Since 2016, patent applications in the materials informatics sector have increased five-fold, and the pace of patent filings is accelerating. This of course brings both reward and risk for those venturing into the materials informatics sector, of the sort Kirkaldy could never have envisaged.

‘FACTS NOT OPINIONS’ was the first distant whisperings of a materials informatics revolution that is now in full swing - and we can’t wait to see where those facts take us next.

Our materials science team has a wealth of experience in all areas of materials science, including computational materials and materials informatics. If you would like to speak to us about patenting inventions in materials informatics, or any branch of materials science, get in touch!

12.03.2025

IP and SpaceThe space sector has seen remarkable advancements in recent years, with innovations spanning propulsion systems, life support technologies, advanced navigation, telecommunications, and space farming.

13.02.2025

Packaging innovations and IPAhead of the Packaging Innovations & Empack exhibition, Nathaniel Taylor takes a look at the forms of Intellectual Property (IP) typically arising in the packaging industry and the boundaries between the different forms of protection that might be available. In the packaging industry, companies typically seek various forms of IP protection for packaging innovations, including patents, registered designs, and trademarks.

Thank you