28.11.2023

Nathaniel Taylor interrogates Toyota’s patent portfolio in the hunt for the technical details behind their recent "battery breakthrough". Does their solution lie in a new solid state cathode material?

Thank you

Nathaniel Taylor, UK and European Patent Attorney at Keltie LLP, will be one of 10,000+ attendees visiting the London Electric Vehicle (EV) show this week (28th to 30th November), where engineers, manufacturers, suppliers, thought leaders, and decision-makers, will provide a comprehensive showcase of the electric vehicle industry.

Ahead of the event, Nathaniel looked back at the most significant developments in the EV industry this year, which included the announcement of a significant technological breakthrough for solid-state battery technologies by Toyota Motor Corporation (Toyota).

The breakthrough was posed as a potential ‘game-changer’ for the automotive EV industry, allowing Toyota to halve the weight, size and cost of batteries in their electric vehicles [1].

However, the technical details in the announcement were very limited, leaving the question - how have Toyota succeeded where others have failed?

In this article, Nathaniel interrogates Toyota’s patent portfolio in the hunt for the technical details behind the breakthrough and poses that the solution might lie in the formation of a clay-like solid electrolyte composition for the battery electrodes, providing a simpler manufacturing process and more uniform battery properties.

Toyota have been slower than rivals to roll out electric vehicles. However, in June 2023, Toyota announced a significant technological breakthrough in relation to their solid-state batteries and it was suggested that the breakthrough would allow them to produce an EV with a range of 1,200km (745 miles) and a charge time of less than 10 minutes [1].

With this level of improvement, Toyota would be set to narrow the gap on Tesla, and the potential for the technology has been reflected by an approximate 30 per cent increase in Toyota’s share price since the plans were announced [2].

Indeed, solid-state batteries have long been heralded by industry experts as the most promising technology to solve charging and capacity problems in EVs. However, to date, solid-state batteries have remained too expensive and difficult to produce, forcing manufacturers to focus their efforts on developing liquid-based lithium-ion batteries.

As might be expected, technical details from the announcement were very limited. However, a few details were revealed that a curious Patent Attorney might use to investigate where the breakthrough lies:

This information can be used to inform a search for relevant patent applications that might reveal the technical details behind the breakthrough.

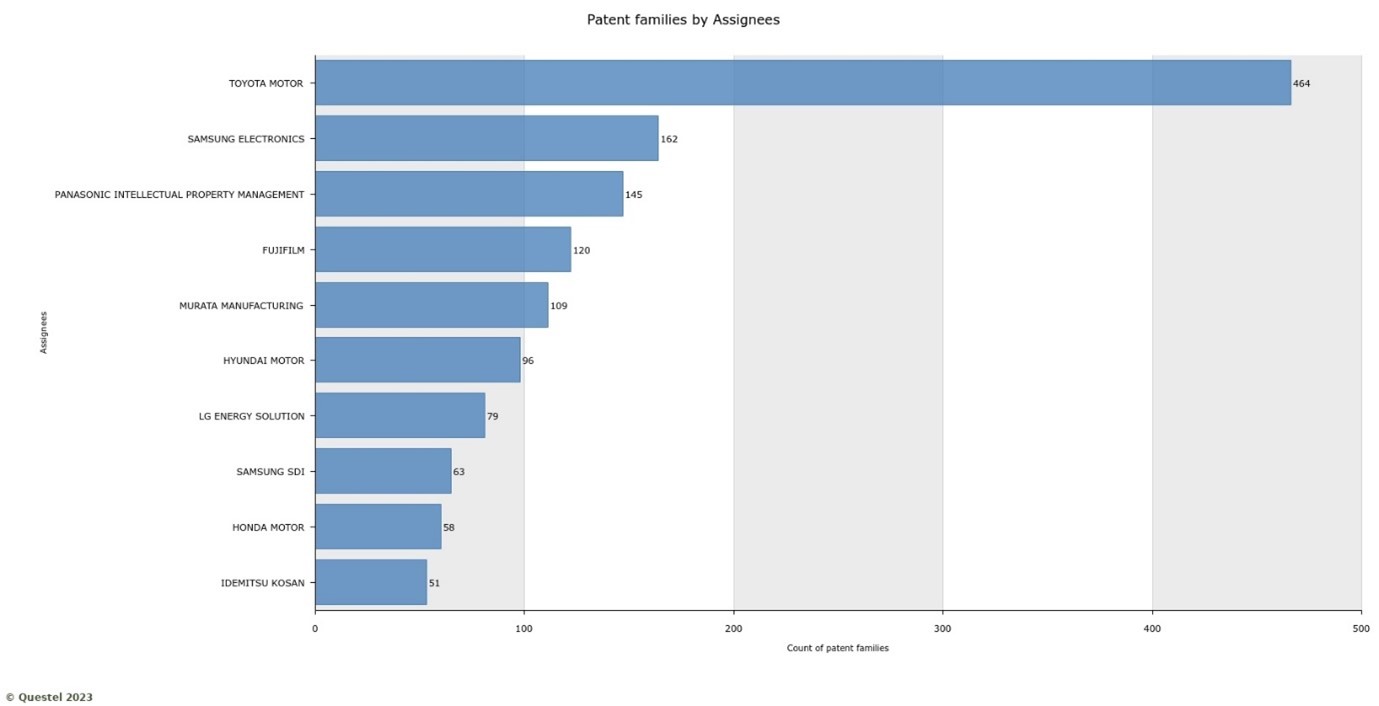

The first thing to note is that Toyota is dominating the race to develop the next-generation power source for electric vehicles, owning more than 450 granted patents relating to solid-state batteries and their methods of manufacture*. This is almost three times as many as their next closest rivals.

When we took a closer look into the patent portfolio, we found that Toyota have relatively broad coverage in this technical field. The portfolio has a particular focus on sulphide-based solid electrolytes, and methods of manufacturing electrodes, but also includes various solutions for materials, battery structures, and ways to achieve particular charge/discharge characteristics.

In relation to the latest breakthrough, the available information indicates that Toyota have come up with a materials solution - most likely involving a sulphide solid electrolyte - for resolving the problems concerning the complexity of the production process and the durability of the resulting batteries. Indeed, since making the announcement of the technological breakthrough, Toyota have restated their confidence in sulphide-based solid electrolytes as the “most promising solution for battery EV issues” [4].

Between 2010 and 2020, Toyota’s patent filings reflect research and development efforts concentrated on both wet and dry methods for manufacturing electrodes. To give one such example, EP2686898A1 discusses a solution for providing a practical slurry for a sulphide solid electrolyte material. However, it appears that the most recent technological breakthrough might lie in an alternative method of manufacturing electrodes, involving the formation of a clay-like solid electrolyte composition, as disclosed in WO2023223627A1 (filed 2 March 2023), for example.

As described in WO2023223627A1:

the clay-like composition is formed by combining a deformable solid electrolyte, such as a Sulphide solid electrolyte, with a particulate active material, where the solid electrolyte can be crushed into particulate / powder form and kneaded together with the active material to effectively adhere the solid electrolyte to the active material.

The resulting composition has a greater viscosity, lacking the fluidity of a slurry, so that a shearing force is easily applied to the mixture when solidified and the clay-like composition can be formed into an electrode directly, or through mixture with an additional solvent.

The promise of this manufacturing technique is further confirmed in other patent applications, such as US2023378426A1 (jointly filed by Toyota and company Prime Planet Energy & Solutions).

US2023378426A1 discloses:

a method of manufacturing an electrode sheet that involves blending the raw materials of the electrode mixture into particulates, before kneading them together to form a paste / clay-like mixture, which is applied to a substrate, before being dried, pressed, and cut, to form a strip of the foil-like electrode sheet.

US2023378426A1 is specifically concerned with refining the drying conditions, such as the temperature and/or drying time, during the manufacturing process to produce strips of a uniform specific surface area. In this respect, more granular refinements of the process, as disclosed in US2023378426A1, reflects the ongoing development of this technology.

More technical details will be revealed as further patent applications are published, but for now it seems reasonable to expect that this clay-like composition might provide the most promising route forward for the development and adoption of solid-state batteries.

If you would like to speak to our team about patents in the automotive or energy storage sectors, get in touch with Nathaniel.

* Search results from Orbit Patent Database, using Keyword searching and CPC classification codes such as H01M10/0562.

[1] FT. https://www.ft.com/content/87cb8e92-8e82-4755-8fc3-2943f8f63e1d

[2] MSN. https://www.msn.com/en-gb/money/watchlist?tab=Related&id=a24bh7&ocid=ansMSNMoney11&duration=1D&src=b_secdans&relatedQuoteId=a24bh7&relatedSource=MlAl

[3] Toyota. https://global.toyota/en/newsroom/corporate/31477926.html

[4] FT. https://www.ft.com/content/f4353d2b-f941-475b-bc1d-a64475503ea6

27.08.2025

Leading the way in life sciences IP: Q&A with Laura KehoeKeltie is rated as ‘Outstanding’ in the 2025 WIPR UK Patents Rankings. This ranking recognises the top firms in UK patent law for their expertise, reputation and client service. This is a powerful endorsement of Keltie’s expertise in supporting innovation across a wide range of sectors, including life sciences, chemistry, software and engineering. Keltie’s team has long been known for its collaborative, commercially grounded approach to IP, and this ranking is a reflection of that continued success.

09.12.2025

Case Law Review: Board of Appeal Decision T 2353/22A recent Board of Appeal decision upheld the COMVIK test as the gold standard for determining whether computer-implemented methods are technical or not, and assessing inventive step.

Thank you